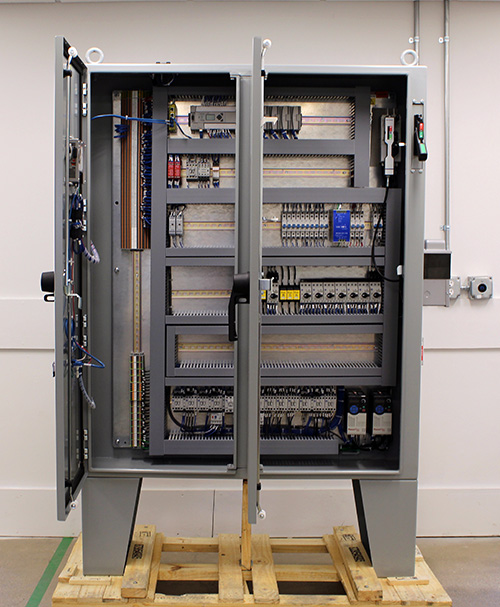

Individually built to each customer’s specifications and control panel component requirements.

Our industrial control panels are built using the highest-quality components and materials in the industry. We 100% meet NEMA standards and are a UL508A-certified shop.

Our industrial and OEM control panels are built to the highest quality standards.

- All stocked electronic componentry is housed in a climate-controlled facility to protect against temperature and humidity.

- This ensures our control components have the highest likelihood of a long service life.

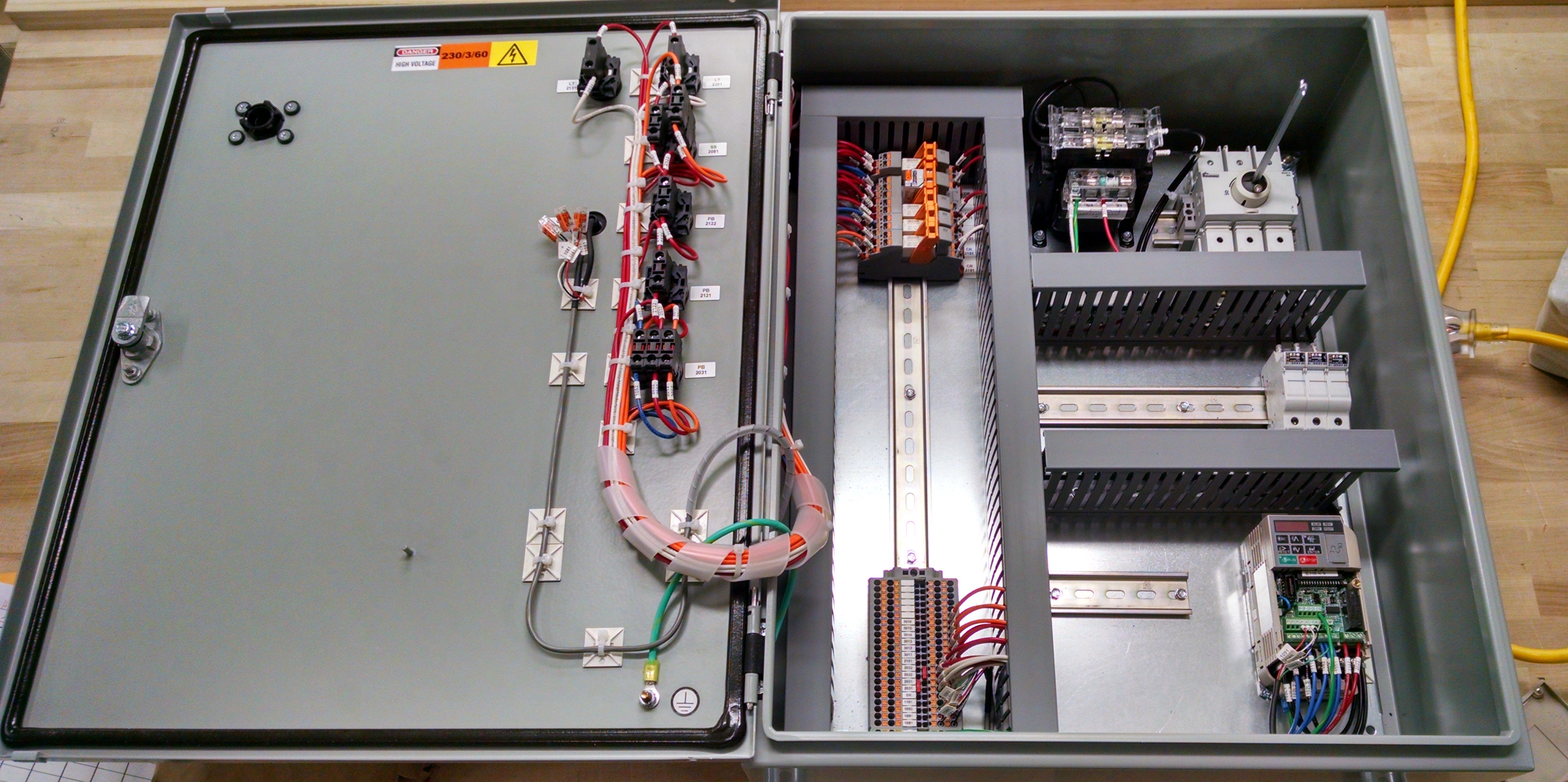

- We use MTW (machine tool wire) for our control wiring. This high-grade wire provides superior function and ensures a professional, advanced look to your panel.

- Less fatigue on the wire as it winds through the control panel to extend service life

- Flexibility allows for easier part changeouts

- Easier troubleshooting in the unlikely event of a control panel problem

- We use ferrules in all of our panel builds.

- Loose wire strands in industrial panels are costly and dangerous.

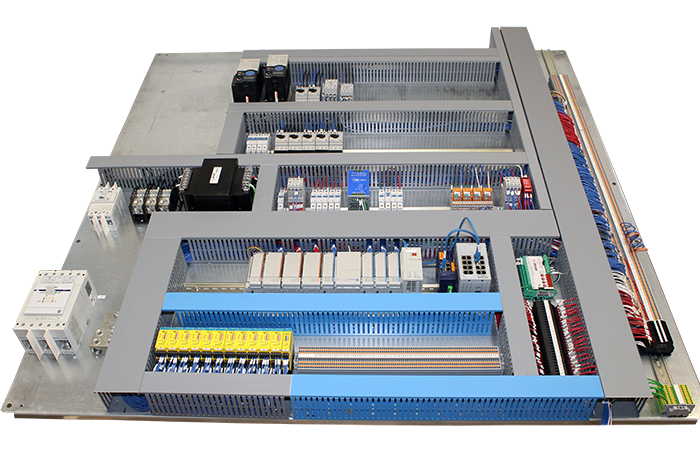

- Rigorous functionality and QC check.

- All our control panels receive complete and rigorous testing before shipping.

We have designed our control panel manufacturing shop with a flexible layout for our work areas. This allows our certified panel builders to move quickly and seamlessly from one design concept to another without set-up costs. Our builders are knowledgeable in various control panel designs and have several years of individual experience.