This whitepaper is for manufacturers who want to achieve more control over increasing energy costs. Improving energy management is important not only for the company, but is also an essential component in achieving a high-growth, low-inflation economy.

Larry West, Sales and Automation Manager at KMC Global Controls & Automation in Kalamazoo, Michigan has traveled the world for several years as a service technician and engineer in the manufacturing and industrial sector. He has seen first-hand, the use and waste of energy.

The reasons for energy waste typically are not sinister in nature. As Larry points out, “no one person sets out to waste energy. However, the decisions about how operations and equipment should run can lead to wasteful and costly consequences.”

This report does not cover energy usage as it pertains to building services, computing, and other administrative energy. Energy waste in these areas are important to address, however, this paper focuses on machine and process energy waste. It will discuss the nature of energy waste, what the most common offenders are as it relates to industry, and what can be done to reduce it.

Industry uses more than one-third of all energy consumed in the United States, and when product transportation is factored in it is an even greater number. According to a report released in 2013 by Energy Central, the United States has taken over the top spot for energy waste. The report goes on to say that the US wastes more energy than it uses effectively-a total sum of 58% of its energy is wasted.1 In a 2017 report, the New York Times states that America had increased that energy waste to 66%2-not the worst offender this time, but still close to the top.

The Push Towards Efficiency

Many believe that the climate is changing due to the disruptive nature human activity, for this group, the reasons to change wasteful ways and become more ‘green’ is apparent and must happen immediately.

Others, that are not on board with climate change believe human activity does not have much to do with planetary temperature shifts. Some may even say that energy is cheap, abundant, and vast, so there is little use for wasting time trying to make processes more efficient-after all, current processes may seem to work pretty well.

In either case, it all comes down to responsible stewardship of natural resources and taking a full account of the interest of society and future generations. Wasting energy today is using resources that belong to future generations.

Electrical Energy Waste in the Manufacturing Sector

As mentioned before, energy waste is not sinister, but typically a mindset that seems harmless. For instance, an employee may decide or be instructed to leave a motor run even when it is experiencing intermittent activity. It is easy to program a pause to shut off a motor and then automatically re-start when a process requires its operation, but to the user that can seem risky.

An employee or business owner may think that because these motors are small they don’t use a lot of electricity. The fact is, even small motors running idle draw electricity and this wasted energy adds up over time.

For example, generally a small motor between .5-5horse (for this calculation an average of 2-horse was used) will draw about 1,500 watts/hour. That one motor running for one day will use 36,000 watts (3.6 kilowatts) of energy. Considering that nation wide there are roughly 300,000 factories in the US, how many motors are running idle right now?

Another example is found in the Pharmaceutical industry, where energy waste is the largest among all industrial sectors. As patient medications have become more personalized and specific ‘million-bottle runs’ is a thing of the past and so-called micro runs are now commonplace. These lines are stopped often to adjust things such as the number of tablets or change in dosages. During that time lights are on, but the line is not producing.3

Key Offenders of Energy Waste

Key offenders of energy waste are the principal operations that run for periods of time without cause, such as the pharmaceutical example in the section above. In addition, conveyor motors, blowers, pumps, vessel agitation, and blending are a few examples of equipment that is left on for long periods of time even when product or materials are not being run.

For instance, a process that has a conveyor taking aborted material away. This conveyor will typically run for hours-if not days-without transporting any material.

Curbing the Wasted Energy Cycle

Reducing wasted energy should start with the basics. Don’t try to fix everything at once because that leads to failure and reverting to the logic that it is just easier to leave it alone. Find a simple energy waster and its most simple problem.

Take the example about the material conveyor in the section above. This problem could easily be solved with a slight bit of programming and a sensor. When production is in operation the conveyor is paused and, when material is present to the sensor, the conveyor will run for a given period of time after the sensor is clear-allowing the conveyor to transport the aborted material to its destination and then pause again until more material is available and ready for transport.

Once simple energy wasting solutions have been mastered, other efficiency factors can be applied, such as:

What Do the Energy Companies Have to Say?

Go to the local energy company’s website and it will likely be filled with green energy initiatives. Most energy providers are looking to renewable (green) energy as their next tool in energy acquisition. Mandates and public sentiment are the key drivers for this shift.

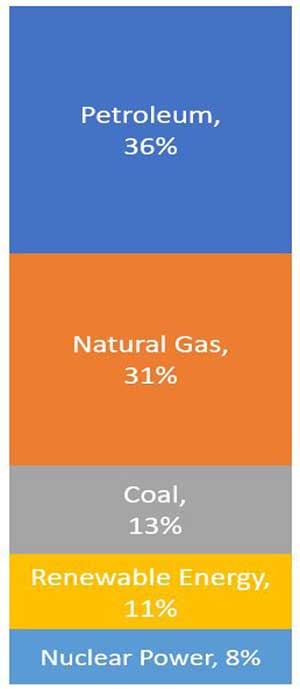

However, green energy technology will not be able to keep up with continued and rising demand, so companies must learn ways to reduce usage and become more efficient by utilizing sustainable energy resources to overtake coal, gas, and nuclear.

Most energy providers have initiatives and incentives to help companies use less of their product (energy). Think about that for a minute, how many companies solicit and reward customers for using less of their product. That fact really drives home the kind of potential calamity we face without addressing sustainability and most importantly, energy waste.

The final tool that energy companies ultimately use to reduce the amount of energy being consumed is cost. The cost of electricity will continue to rise. It would be remiss not to point out that, according to a May 2019 article in Forbes Magazine, renewable energy costs continue to tumble over the past year,6-making it competitive with other energy sources. This is good news for our energy sector, but we must make serious changes in usage to make this viable.

Manufacturers in the United States and across the world are introducing a variety of innovative technologies, new business processes, and management techniques to encourage increased efficiency in the use of industrial energy.

One highly effective method of saving energy without the need for additional resources, is to automate machinery by updating or installing control systems to the existing process. Information can be obtained from external and internal datasets compiled automatically by this monitoring and then analyzed where faster, better autonomous decisions are made to optimize energy use.

Automated machine energy monitoring and information technologies allow managers to capture the value of industrial costs like energy. Management teams can monitor energy spikes, peak hours, weekend use, wasted hours, and more. In addition, innovative technologies such as controls and automation can:

Most initiatives are unsuccessful because its is not clear who is responsible. Pull a team together to oversee energy saving efforts.

Have the equipment programed to run outside of peak hours—if possible. Using intelligence collected from automated machine energy monitoring consider what requires the most energy to run. Equipment running during peak hours contributes to up to 30% of an operations utility bill.

Have machine controls programed to be turned off for a period of time during the weekend or off-shifts. Then, have them programed to start back up when they are required for use. Remember to stagger start-up so there is not a large spike in energy use.

Air compressors account for around $3.2 billion in energy waste annually.

HVAC Systems account for nearly 52% of a facility’s total energy use. Make these units more efficient by installing a programmable thermostat, investing in a demandcontrolled ventilation system, or make simple repairs and insulation of the ducting.

There is a shift in business thinking. Companies are now adopting guidelines to ensure that their operations look at energy efficiency as a large part of their sustainability efforts. Unfortunately, many businesses are still adopting a philosophy of “if it ain’t broke don’t fix it.” For operations who take the approach of doing nothing towards becoming more efficient, the high costs of energy waste quickly add up to significant loss of potential profit growth.

By making small changes to lighting, air conditioning usage, and switching off equipment when not in use, there is a big difference to yearly energy consumption. Once the basics are mastered, energy efficiency measures such as power factor correction, or energy monitoring pay big dividends as they provide a better understanding of which systems consume the most energy to help management make more informed decisions when creating a more efficient process.

Larry West is the Sales and Automation Manager for KMC Global Controls & Automation and has more than 18 years of field service and engineering experience-including electrical engineering—in a wide variety of industries including process manufacturing, metalworking operations, and more. KMC Global Controls & Automation provides a single point of contact for a wide variety of industrial controls and automation needs.

Teresa Phillips is the Senior Marketing Specialist for PRAB Inc. and has over 18 years of marketing experience within the manufacturing sector. PRAB is a sister company of KMC Global Controls & Automation- providing metal chip processing and fluid filtration equipment, industrial water and wastewater treatment systems, and conveyors—equipped with KMC Global Controls & Automation technologies.

1 NRG Business, US Now Leads in Energy Waste – https://www.energycentral.com/c/ec/us-now-leads-energy-waste

2 New York Times, Why Is America Wasting So Much Energy? – https://www.nytimes.com/2017/11/07/opinion/bipartisan-energy-efficiency.html

3 National Association of Manufacturers, Efficiency and Innovation in US Manufacturing Energy Use – https://www.energy.gov/sites/prod/files/2014/05/f15/energy-nam.pdf

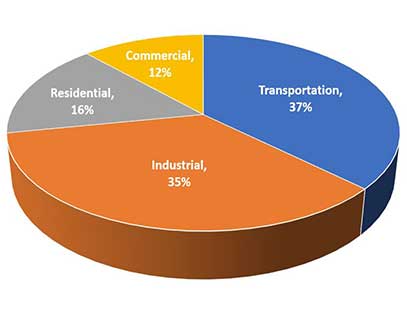

4U.S. Energy Information Administration (eia), U.S. Energy Consumption by Source and Sector, 2018 Chart – https://www.eia.gov/energyexplained/us-energy-facts/

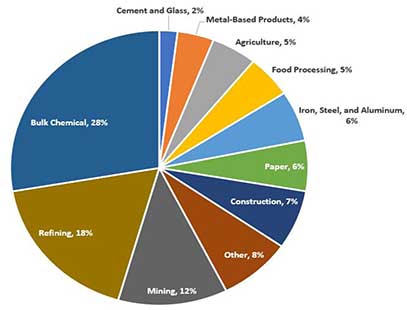

5 US Energy Information Administration, Independent Statistics and Analysis – https://www.eia.gov/energyexplained/use-of-energy/industry.php

6 Forbes Magazine, Renewable Energy Costs Take Anoter Tumble, Making Fossil Fuels Look More Expensive Than Ever – https://www.forbes.com/sites/dominicdudley/2019/05/29/renewable-energy-costs-tumble/#5f047b0ce8ce

7Constellation Blog, 6 Ways Manufacturers Can Reduce Industrial Engergy Costs – https://blogs.constellation.com/energy-management/6-ways-to-reduce-industrial-energy-costs/

KMC Global Controls & Automation provides a single point of contact for a wide variety of industrial controls and automation needs. We offer a variety of services, including Certified UL 508A-listed industrial control panels, control panel design, automation & integration with smart programming, and, remote one on-site automation to assist customers with commissioning equipment, program changes, troubleshooting electrical control components, schematic and project review, and control panel wiring clean-up.